Pumpkin seed processing line

- TFBGZ-400

- China

- 7-20 days

- 30 sets

01. This equipment is used to dehull pumpkin seed,gourd seed,zucchini seed and watermelon seed.

02. Wet method for dehulling.

03. Production cost is reduced by bell-crank driven transmission.

04. The best dehulling performance can be achieved by adjusting frequency inverter of the dehullers.

05. ISO9001:2015&CE certified.

Pumpkin seed huller TFBGZ-400

Functions and Features

The pumpkin seed huller can complete the dehulling, shells-removing and seed-kernel separating of pumpkin seed(gourd seed, zucchini seed and water melon seed) at one time. This equipment adopts wet method for dehulling, and it features high percentage of whole kernel, compact structure, low loss, easy operation and maintenance, etc.

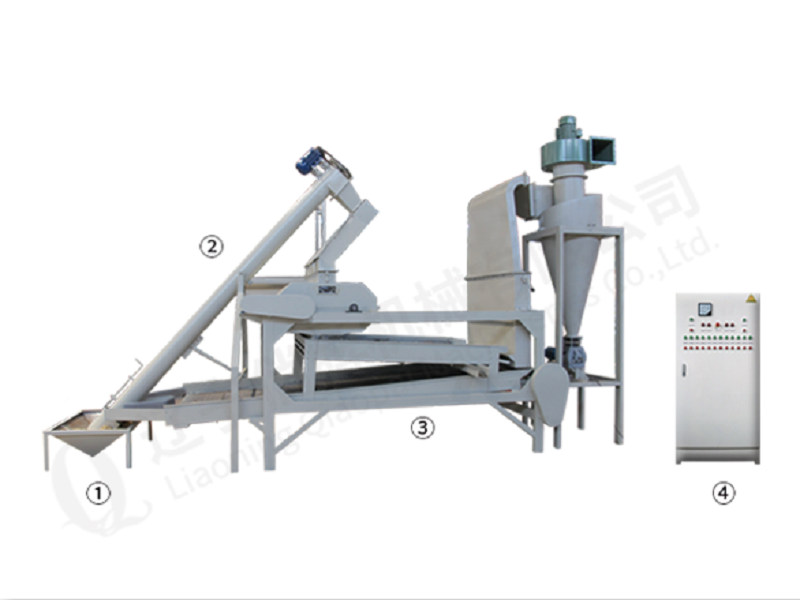

Component

①input hopper ②bucket elevator ③main part of the equipment(dehullers, air separator and seed-kernel separator) ④electric control cabinet

Technical Parameters (dehulling&separating unit)

|

Power |

10.05 kw(380v) |

|

Input capacity |

300 - 400 kg/h |

|

% of whole kernels (broken kernel less than 1/2 of whole one) |

95% min. |

|

% of inshell in kernels |

2% max. |

|

Overall Dimension (L*W*H) |

7.5 x 2.2 x 3.8 m |