Dehulling Equipment

-

Pistachio nuts sheller

1. High efficient

Email Details

2. ISO9001:2015 and CE certified

3. International warranty and technical support

4. Competitive price -

Oat shelling equipment

01. this equipment is the optimum pretreatment equipment for oat meals production.

Email Details

02. twin-dehullers design increases dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw oats.

03.unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max.

04. ISO9001:2015&CE certified. -

Badam Processing Equipment

1. High efficient

Email Details

2. ISO9001:2015 and CE certified

3. International warranty and technical support

4. Competitive price -

Tartary Buckwheat Sheller

01. Unique dehuller design secure the integrity of the tartary buckwheat shells/husks.

Email Details

02. Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max.

03. ISO9001:2015&CE certified. -

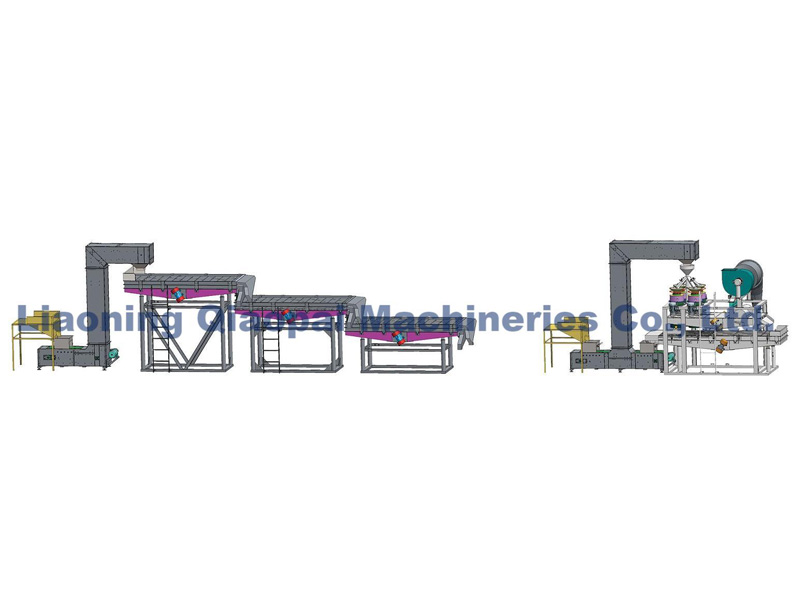

Pumpkin seed processing line

01. This equipment is used to dehull pumpkin seed,gourd seed,zucchini seed and watermelon seed.

Email Details

02. Wet method for dehulling.

03. Production cost is reduced by bell-crank driven transmission.

04. The best dehulling performance can be achieved by adjusting frequency inverter of the dehullers.

05. ISO9001:2015&CE certified. -

Pakistan Pine Nuts Shelling machine

01. this equipment is used to dehull Pakistani pine nuts.

02.unique multi-functional cleaner design secure the sunflower seeds going into dehullers are pre-cleaned, big impurities, small impurities,light impurities&empty seeds, and small seeds can be sorted out properly.

03. unique dehullers design secures high percentage of whole kernels and reduces the broken kernels rate efficiently.

04.unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max.

05. ISO 9001 : 2015 & CE certified.Pakistan Pine Nut Shelling machine Pakistan Pine Nuts Shelling Equipment Pakistan Pine Nuts Shelling MachineEmail Details