Sunflower Seed Cleaning Dehulling and Separating Equipment

- TFKH-1500

- China

- 7-20 days

- 30 sets

1. This equipment is used for both confectionery kernels and bakery sunflower kernels production

2. Unique multi-functional cleaner design secure the sunflower seeds going into dehullers are pre-cleaned, big impurities, small impurities,light impurities&empty seeds, and small seeds can be sorted out properly.

3. 4 of larger diameter dehullers design increase dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw sunflower seed

4. Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max.

5. Wider seed-kernel separating screen makes efficient separaration and better separation performance.

6. ISO 9001:2015 and CE certified

Sunflower Seed Cleaning Dehulling and Separating Equipment TFKH-1500

Functions and Features

This equipment can complete the cleaning, dehulling, shells-removing and seed-kernel separating of sunflower seeds at one time, and it's the optimum choice for sunflower kernel processing industry in the world today. It features high dehulling rate, high percentage of whole kernels,high automation degree, easy operation and maintenance, etc.

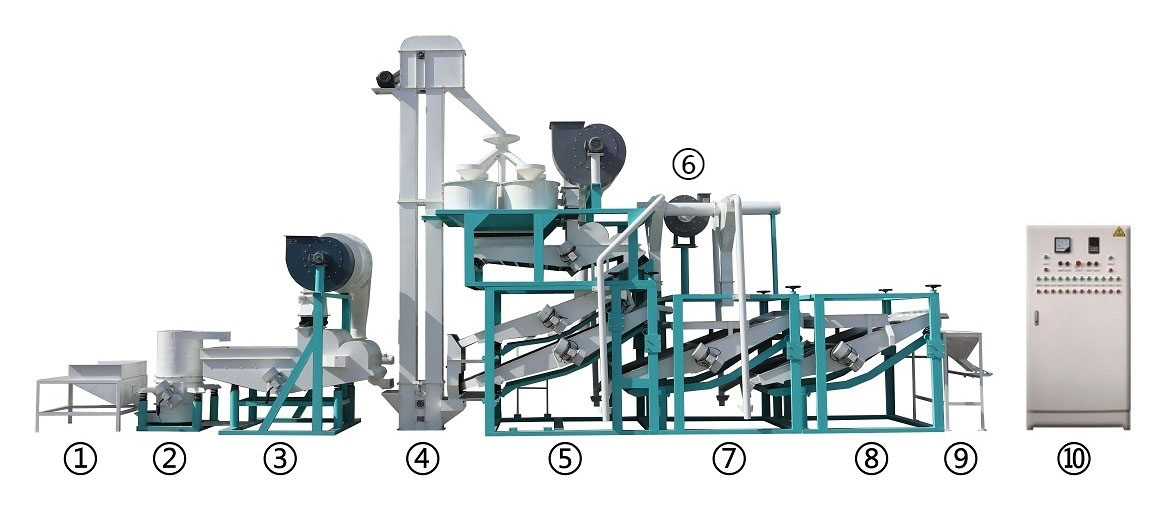

Component

①input hopper ②spiral elevator ③multi-functional cleaner ④bucket elevator ⑤main part of the equipment(dehullers, air separator and seed-kernel separator)⑥pneumatic system of back-flowing materials⑦seed-kernel re-separator1⑧seed-kernel re-separator2⑨kernels bin ⑩electric control cabinet

Technical Parameters

| Power | 20.24 kw (380v) |

| Input capacity | 0.8-1.25 mt/h |

|

% of whole kernels (broken kernel less than 1/2 of whole one) |

90% min. |

| % of inshell in kernels | 5% max. |

| Overall Dimension (L*W*H) | 13.1 x 2.92 x 5.4m |