Sunflower Seed Dehulling and Separating Equipment

- TFKH-1500 Horizontal Model

- China

- 7-20 days

- 30 sets

01. This equipment is used for both confectionary kernels and bakery sunflower kernels production

02.Unique multi-functional cleaner design secure the sunflower seeds going into dehullers are pre-cleaned, big impurities, small impurities,light impurities&empty seeds, and small seeds can be sorted out properly.

03. 4 of larger diameter dehullers design increase dehulling capacity, with frequency inverter equipped with electric control cabinet to adjust the frequency according to physical moisture of the raw sunflower seed

04.Unique shells-removing design makes all the shells aspirated properly, % of kernels in shells is 0.5% max.

05.Seed-kernel separating screen makes efficient separaration and better separation performance.

Sunflower Seed Dehulling and Separating Equipment TFKH-1500 (Horizontal Model)

Functions and Features

Sunflower Seed Dehulling and Separating Equipment TFKH-1500 (Horizontal Model) is a patented product of Qiaopai company and is the independent intellectual property of Qiaopai company. It contains 7 national patents.

This equipment provides an integral solution for sunflower seed kernels Industry. It consists of cleaner, dehullers and seed-kernels separators. It features of minimum broken rate,thoroughly separation of shells,high percentage of whole kernels, easy operation and maintenace etc.

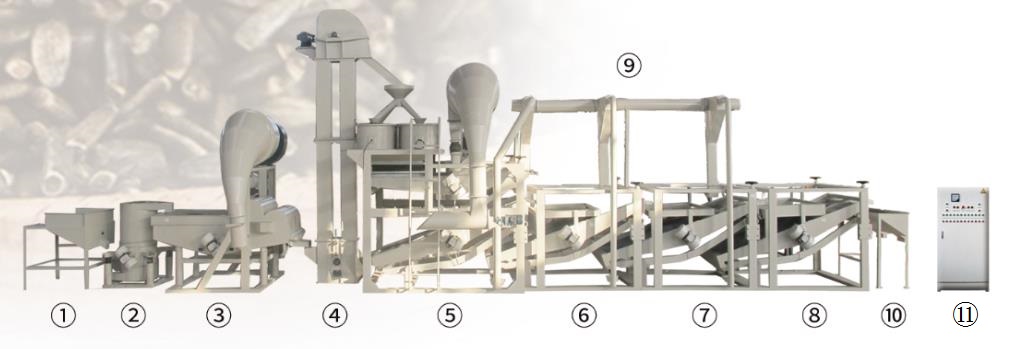

Component

①input hopper ②spiral elevator ③multi-functional cleaner ④bucket elevator ⑤main part of the equipment(dehullers, air separator and seed-kernel separator)⑥pneumatic system of back-flowing materials⑦seed-kernel re-separator 1⑧seed-kernel re-separator 2⑨seed-kernel re-separator 3⑩kernels bin⑪electrical control cabinet

Technical Parameters

|

Power |

17.7 kw (380 v) |

|

Input capacity |

0.7-1.0 mt/h |

|

% of whole kernels (kernels less than 1/2 whole kernels are brokens) |

90% min. |

|

% of inshell in final kernels |

5% max |

|

Overall Dimension (L*W*H) |

14.75 x 2.9 x 4.4 m |